MOLDING - DIE SLIDE INJECTION

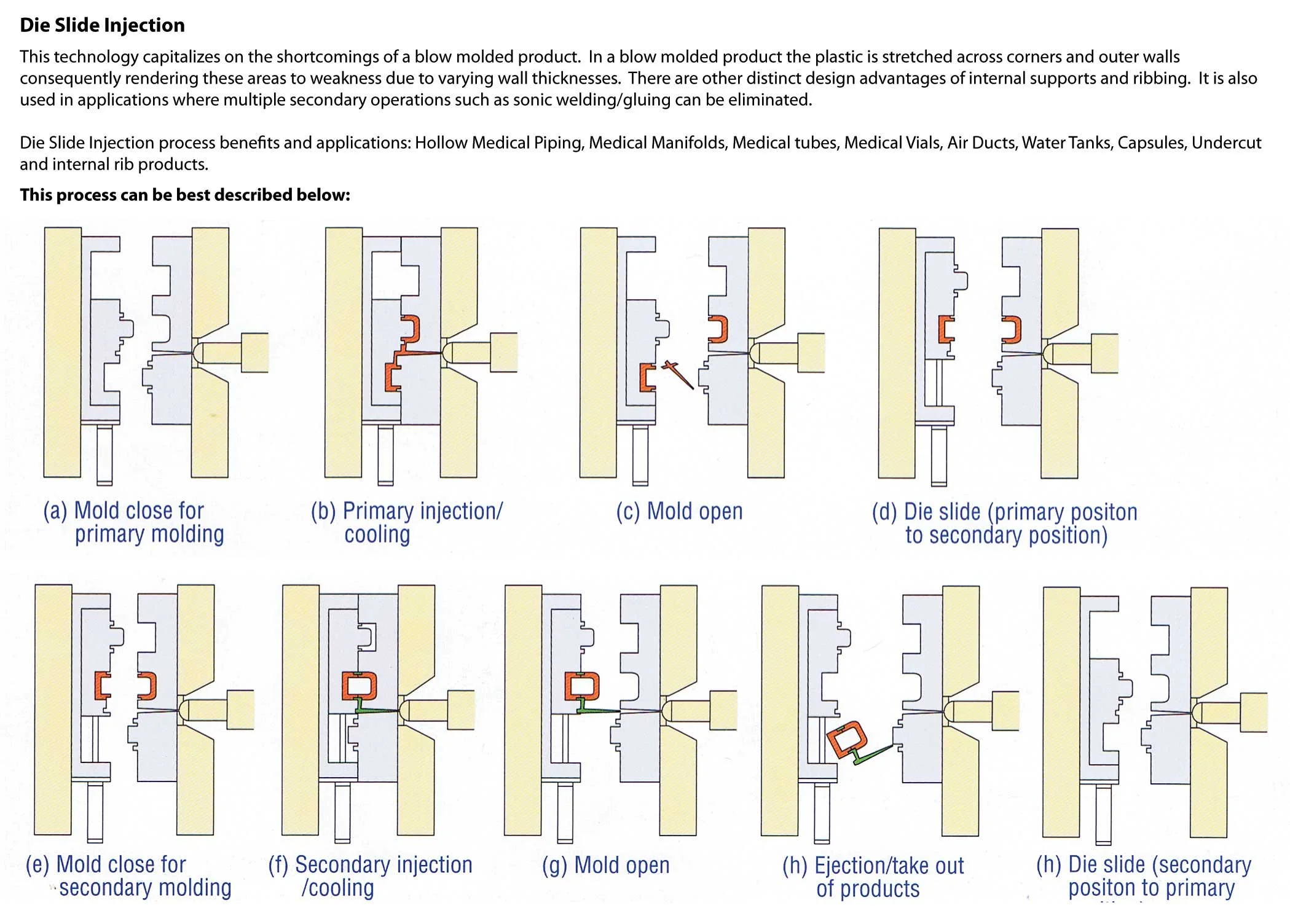

This technology capitalizes on the shortcomings of a blow molded product. In a blow molded product the plastic is stretched across corners and outer walls consequently rendering these areas to weakness due to varying wall thicknesses. There are other distinct design advantages of internal supports and ribbing. It is also used in applications where multiple secondary operations such as sonic welding/gluing can be eliminated.

Die Slide Injection process benefits and applications: Hollow Medical Piping, Medical Manifolds, Medical tubes, Medical Vials, Air Ducts, Water Tanks, Capsules, Undercut and internal rib products.

This process can be best described below: